SOMEHOW

We happened to get two broken truss rods in one month.

Judging by how much rust was on the broken end it had been sitting for quite some time.

You can see in the first photo how much rod is sticking out from the nut.

As the nut is turned it kept pulling the broken rod out, not tightening it.

"This is going to be fun" Says TIm

The plan,

Locate the end of the rod.

Cleanly peal back the binding and remove the fingerboard from over the area, remover the broken truss rod and anchor.

Make and install the new truss rod.

Glue the fingerboard and binding back on.

Test the new rod.

Light touch-up leaves the whole thing undetectable.

SUCCESS!!! More than likely better than new.

|

| Since the rod is not attached at the body end it is pulling out |

|

| Ready to go.. |

|

| Using ultra string Neodymium magnets to find the broken end that needs to come out. |

|

| Adding the heat |

|

| Tea Time!!! |

|

| AND......it's off clean. The broken end stuck in there. |

|

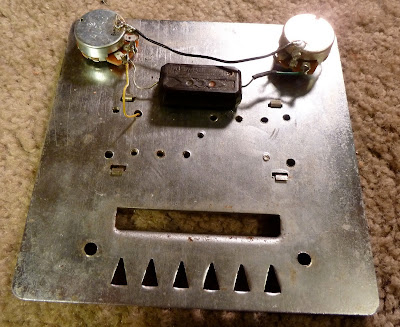

| New larger steel block ready to thread the new rod into. You can see the rod peeking out. |

|

| In place ready to buckle down |

|

| Alignment is very important, 2 hidden locator pins help. |

|

| Add Glue. |

|

| Perfect! The neck straightened right up will all 12 strings with ease. |